Topic: Snapped off Tread Cutter in Rear Caliper Mount

in Forum: C3 Engines, Driveline and Handling

Already a Member?

Click Here to Login

Not yet a Member?

Click Here to Register for Free!

Ok this rebuilding the brakes is getting a little bit frustrating. I bolted on the driver side rear caliper and stripped the treads in the rear caliper mount bracket, so I got a helicoil kit to put in a Helicoil. Then I snapped off the tread cutter. Now I'm in big trouble.

Anyone have any ideas on how to get that out?

SPONSOR AD:: (Our Sponsors help support C3VR)

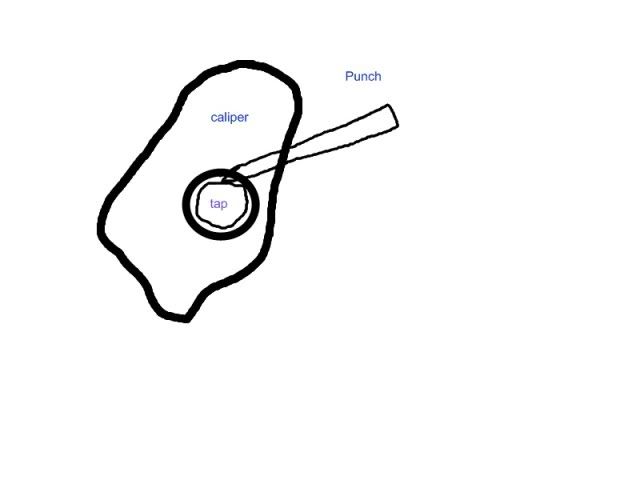

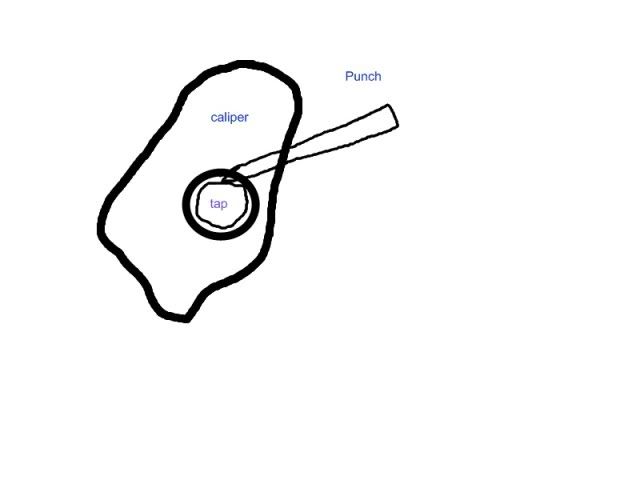

I use a small punch and tap around it on the edge in a counter clockwise direction.

I can't draw for beans.

Moderator

Duncanville, TX - USA

Joined: 11/8/2003

Posts: 20225

Vette(s): #1-1974 L-48 4spd Cp Med Red Metallic/Black deluxe int w/AC/tilt/tele./p/w-p/b/

Am-Fm/map light National/Regional/Chapter NCRS "Top Flight"

#2-1985 Bright Red/Carmine Cp.L-98/auto

Member: NCRS, NCRS Texas, Corvette Legends of Texas

Get one of these things here, or get a new spindle support/caliper bracket...

Click on image for link

Click on image for link

Adams' Apple 2009-08-24 16:55:01

Click on image for link

Click on image for linkJoel Adams

C3VR Lifetime Member #56 ![]()

My Link

(click for Texas-sized view!) NCRS

"Money can't buy happiness -- but somehow it's more comforting to cry in a CORVETTE than in a Kia"

HOWELL, NJ - USA

Joined: 5/18/2004

Posts: 6812

Vette(s): 1979, Targa Blue (72 Color), Pace Car rear spoiler, L88 hood, Dark blue factory interior, 525HP 406, HD 700R4, 370 gears,Steeroids, composite rear spring, TT IIs wrapped in T/A Radials.

Is that what I use when the beer tap is stuck in my mouth?!?!?

LukesVette Homepage

Veteran of Operation Iraqi Freedom

101st Airborne(AirAssault!)

God Bless America

Support Our Troops

Manteca, CA - USA

Joined: 11/20/2005

Posts: 3623

Vette(s): 1978,two tone,Metalic Rootbeer & gold

1975 L48 4 speed

[QUOTE=LukesVette]Is that what I use when the beer tap is stuck in my mouth?!?!?  [/QUOTE]

[/QUOTE]

That's what your buddies are for Paul. They'll make sure it doesn't stay there permenantly  .

.

Jimmy B.

Just can't wait to get on the road again.

Click to see larger views!

Indy99; your drawing was great, I used a punch and slowly started to back it out. I was overjoyed when I got it out.

Thanks for the tip.

Joel, that is a neat tool. I should likley get one so that the next time this happens I will be prepared.

Just some tips on taping. Check to see if the hole is the right size for the tap you are using. Do your self a favor and use a new tap if possible. There is a chart for the hole size to tap relation. Ask any Machinist for one. I am one so I could provide you with the chart if needed.The harder the material is the slightly larger the hole may be. (within the designed limits for the tap). It is less stressfull on the tap with a larger hole. When you start a tap be sure it gets STARTED AN STAYS STRAIGHT! If you can, chuck the tap in a stand up drill press and run the tap down by hand. Be sure to use some kind of oil. Go EASY on the tap. Run it down a little then back it off. You will feel the built up edge as you start to back it off. Work it down then up. Be EXTRA carefull with smaller taps under 1/4 inch. They are sooo easy to snap. DO NOT FORCE THEM!!! If it feels hard then back off and work it down. Run the tap out of the hole and clear the chips if it is a blind hole (one that has a bottom to it). If it is a through hole it is a lot easier to work with. Reoil,clear the chips from the hole with an air gun or blowing hard if you dont have air. Then run it down a little further.(Chip build up,hole size, a dull tap and to much force are the biggest reasons taps break).Repeat as nessesary. As many times as you want to to clear the chips.Do not get in a hurry. Jp 75 was very lucky that the tap broke out of the hole far enough to get it out. 90% of the time it breaks off down in the hole and very difficult if not imposible to get out. It makes me feel tingly all over when a broke tap is extracted. Good going JP75!

in Forum: C3 Engines, Driveline and Handling

SPONSOR AD: (Our Sponsors help support C3VR)

20111021145147r.jpg)